Budget-Friendly litho printing Solutions for Your Company

Budget-Friendly litho printing Solutions for Your Company

Blog Article

A Comprehensive Overview to Understanding Litho Printing Techniques

The globe of litho printing, a strategy originating from the late 18th century, is an interesting blend of background, art, scientific research and technology. This thorough overview will certainly unwind the complexities of this printing technique, from the structure of litho inks to the obstacles encountered in contemporary applications. As we venture into the ins and outs of lithography, the value of automation and sustainability in guaranteeing its future significance becomes significantly clear. Remain with us as we trip into the fascinating realm of litho printing.

The Historic Advancement of Litho Printing

The historic trajectory of litho printing, an essential innovation in the realm of interaction, is a fascinating story of human ingenuity. The process advanced with the introduction of the rotary press, which substantially increased productivity. Each phase of litho printing's advancement showcases mankind's relentless search of effectiveness and top quality in visual communication.

Deciphering the Scientific Research Behind Litho Printing Inks

Moving ahead in the expedition of litho printing techniques, the focus currently changes to the scientific research behind litho printing inks. The composition of these inks, their drying process, and color mixing strategies form the backbone of this complex art kind. Recognizing these aspects is vital to grasping the craft and attaining the wanted print results.

Composition of Litho Inks

In lithographic printing, the essential duty of litho inks can not be overstated. Pigments, the color-providing components, are finely ground fragments suspended in the car, a liquid that carries the pigment onto the printing surface area. Each component plays an essential part in the final print's high quality, making the precise formula of litho inks a detailed scientific research.

Ink Drying Process

From the structure of litho inks, focus transforms to the fascinating process of ink drying out. Two key methods are used in litho printing: oxidative drying out and absorption. Absorption, on the various other hand, includes the ink seeping right into the paper fibers, which is a much faster process yet can lead to less vibrant colors.

Color Mixing Techniques

While the drying procedure plays a key function in litho printing, the scientific research of shade blending methods holds equivalent significance. This is an intricate procedure that involves the cautious blending of main colors: cyan, magenta, and yellow, in varying percentages to accomplish a wide selection of shades. The addition of black ink, called 'key', aids in regulating the intensity and deepness of the shades. The science behind litho printing inks additionally thinks about the transparency of the ink, which affects how shades overlay and mix. To attain an effective color mix, print experts need to likewise recognize the ins and outs of ink habits, shade concept, and the physical residential properties of the substrate on which the ink is used.

The Art and Layout Elements in Litho Printing

Litho printing takes a breath life into art and design through its unique elements. The procedure includes developing a picture on a lithographic limestone plate or metal plate with a smooth surface. The picture is after that published onto a tool, typically paper, by transferring the ink from home plate. What collections litho printing apart is its ability to replicate intricate styles with high fidelity, making the output nearly identical to the initial art work. This is achieved with the use of various line strategies such as hatching, stippling, and cross-hatching, which enable an array his explanation of tonal results. In addition, litho printing fits a variety of shades, making it possible for musicians to produce lively and vibrant prints. This mix of precision and versatility makes litho printing a recommended selection for several artists and developers.

Modern Applications of Litho Printing Methods

Litho printing techniques have discovered comprehensive use in the modern industrial industry. Its impact and relevance proceed to expand with the advent of brand-new advancements and technologies in the field. This area will discover these modern applications and the transformative duty they play in the printing market.

Commercial Litho Printing Makes Use Of

In today's electronic age, one might question the significance of typical printing approaches. Litho printing continues to be a vital component of the business market. High-volume printing jobs, such as the manufacturing of books, newspapers, and product packaging, rely upon litho printing for its capability to provide superior picture high quality and cost effectiveness. The procedure, which involves moving a tattooed photo from a plate onto a rubber covering and after that to the printing surface area, provides unparalleled uniformity. This makes it optimal for jobs requiring a big print run. Litho printing also offers a wide shade range, above that of electronic printing. This makes it the go-to choice for tasks that require vivid, high-grade color recreation.

Innovations in Litho Printing

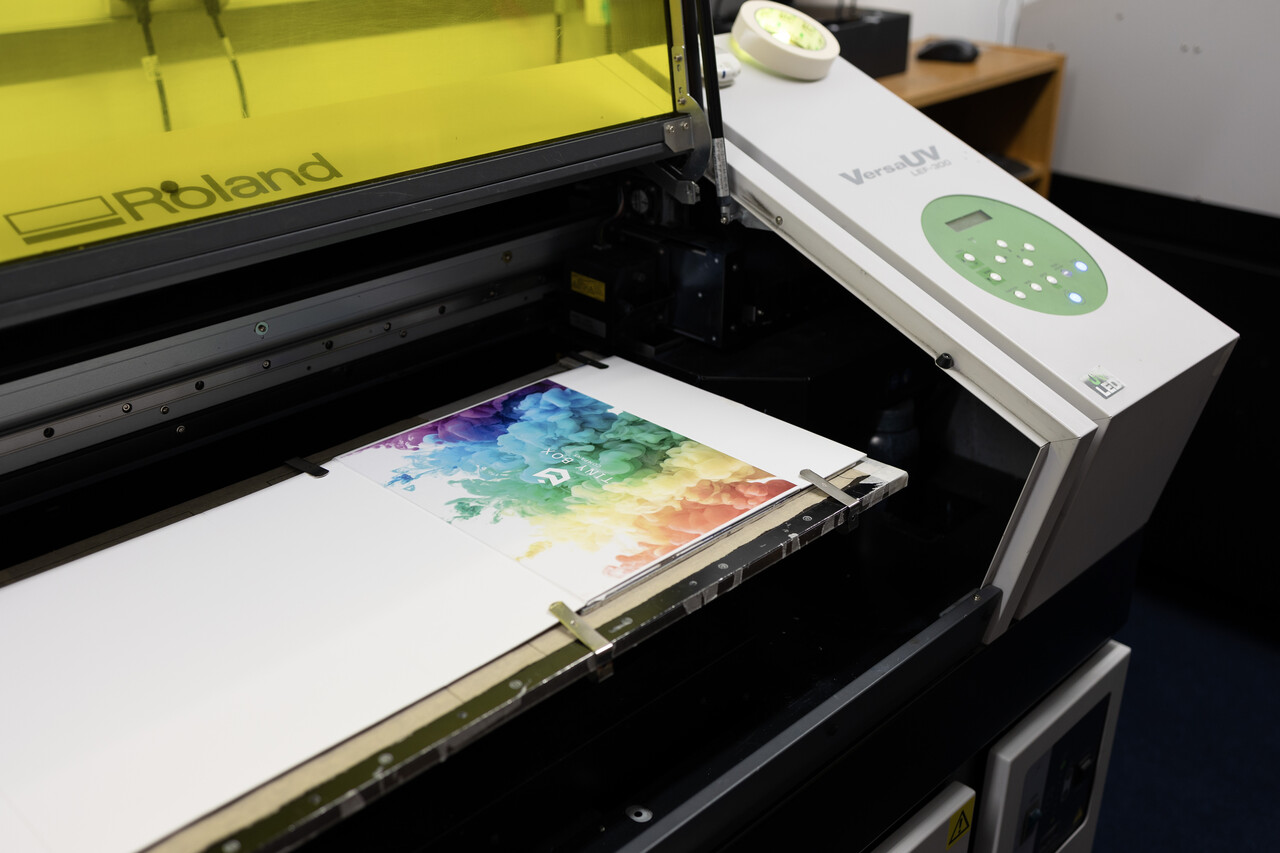

Pressing the limits of conventional methods, modern-day advancements have actually fueled a host of technologies in litho printing. These advancements have not just enhanced the top quality and performance of litho prints but also broadened its application extent. One prominent growth is digital litho printing, which combines the merits of digital innovation with litho's high-grade result. This hybrid model offers faster arrangement times, reduced waste, and makes it possible for on-demand printing. An additional significant improvement is the introduction of eco-friendly inks. These inks, made from veggie or soy-based solutions, have substantially reduced the market's ecological influence. litho printing. In addition, the development of innovative plate technology has streamlined the printing procedure, resulting in sharper pictures and boosted shade integrity. These advancements highlight the enduring relevance of litho printing in the modern globe.

Discovering the Refine of Litho Printing: Detailed

Challenges and Solutions in Contemporary Litho Printing

Despite the precision and tradition that litho printing happily supports, it is not without its collection of contemporary obstacles. Digital litho printing allows for economical short runs and simple modification, resolving the issue of variable data. Therefore, while there are obstacles, the litho printing industry is proactively adapting to fulfill them head-on, ensuring its relevance in the future.

Verdict

In final thought, litho printing, with its abundant history and scientific details, holds a significant area in the print market. The future of litho printing hinges on its ability to adapt to these changing demands, affirming its enduring value in an evolving market.

Report this page